Manual Die Sinking EDM

Electric Discharge Machine (EDM)

Electric Discharge Machine (EDM)

Electrical discharge machine works by using the erosion caused by the impulse discharge between the electrode and the conductive material, which has been used in the production of dies....

Amplifier

Amplifier

The amplifier is the servo drive for driving and controlling servo valves and proportional valves. It can realize high accuracy control of all kinds of valves. Servo power amplifier can be composed with other hydraulic systems and measuring transducers into an electro-hydraulic servo system, such as...

Electro-hydraulic Servo Valve

Electro-hydraulic Servo Valve

Electro hydraulic servo valve can measure the hydraulic oil according to input signal, then to control position, speed, pressure or force in the electro hydraulic systems (generally the pistons and plungers)....

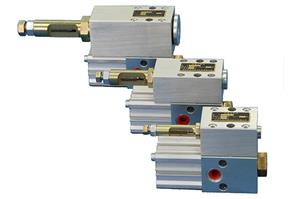

Electro-hydraulic Proportional Valve

Electro-hydraulic Proportional Valve

Electro hydraulic proportional valve is a hydraulic component, which can translate electrical signal to displacement signal by an analog electric-machinery converter. When this valve acts, the electric-machinery converter will response the input signal to move the valve core, change the opening size...

Grease Injection Valve

Grease Injection Valve

Grease injection valve is an equipment that can output high pressure medium quantitatively. It is the most important part of the quantitative filling machine, which can fill many different kinds of high viscosity oil such as lithium grease, calcium soap grease, other semisolid oil and adhesives. Qua...

Single Axis CNC EDM Machine

Single Axis CNC EDM Machine

Single axis CNC EDM machine uses a single axis (Z-axis) with auto-feeding control system (including servo feed system and parameters control system), other axes are manual control axis (X-axis and Y-axis)....

Three Axis CNC EDM Machine

Three Axis CNC EDM Machine

With auto-feeding control system (including servo feed system and parameters control system), three axis CNC EDM machine has wonderful performance on automation and control precision. It is widely used in the field of mould production for electronic component, automation, information and communicat...

CNC EDM Blade Grinder

CNC EDM Blade Grinder

CNC EDM grinder is a machine that can produce PCD cutters through grinding. With 4 CNC controlled axes and 2 manual axes, which is used for the complete processing of PCD tipped tools....

The manual die sinking EDM incorporates rigid heavy duty Michiganite castings designed using Finite Element Analysis to ensure high accuracy machining. Preminger grade ultra fine Class 5 ball screws, high resolution 0.0002” linear optical scale for the X,Y and Z axis coupled with high quality linear ways produce smooth, precise operation.

Features

1. Fast response MOFSET machining circuits

2. 15” easy to read, full color LCD flat screen display and 32 bit industrial grade computer

3. 90 sets of Auto Memorized user machining parameters

4. Auto Set machining parameters from roughing to finishing ( maximum 10 steps)

5. Hardened precision work table with standard T Slots

6. Auto Fire Extinguisher with fire and fluid level sensors

Specifications of Manual Die Sinking EDM

| Item / Model | DS-325-ZNC | DS-430S-ZNC | DS-550-ZNC | DS-755-ZNC |

| X-Axis | 12″ | 16″ | 20″ | 28″ |

| Y-Axis | 10″ | 12″ | 16″ | 22″ |

| Z-Axis (servo) | 6″ | 7″ | 8″ | 10″ |

| Z-2 (workhead) | 8″ | 10″ | 12″ | 12″ |

| Work Table Size | 24” x 12” | 26″ x 14″ | 32” x 18” | 43” x 24” |

| Max. Workpiece Size | 34” × 21” × 13” | 38” × 22” × 14” | 46” × 27” × 17” | 67” × 39” × 22” |

| Max. Workpiece Weight | 880 lbs. | 1,210 lbs. | 2,970 lbs. | 4,400 lbs. |

| Max. Electrode Weight | Platen -176 lbs. | Platen - 220 lbs. | Platen -396 lbs. | Platen -550 lbs. |

| Distance from RAM to Table | 6” - 20” | 6” - 23” | 9” - 29” | 11” - 33” |

| Machine Dimensions (L×W×H) | 96” × 69” × 93” | 96” × 69” × 93” | 153” × 71” × 96” | 174” × 99” × 98” |

| Machine Weight | 2,156 lbs. | 2,530 lbs. | 4,290 lbs. | 4,290 lbs. |

| Tank Capacity | 92 gal. | 100 gal. | 145 gal. | 330 gal. |

Manual Die Sinker EDM

Manual Die Sinking EDM Machinery

Manual Die Sinking Electrical Discharge Machining

Manual Die Sinking Electrical Discharge Machine

Miniature Proportional Valve

Miniature Proportional Valve

Thermally compensated 2-way normally closed (NC) miniature proportional valve designed to maintain accurate and repeatable flow over a wide range of media. Ideal for medical and analytical applications that require precision control and flow up to 56 slpm....

Tag: Low Flow Miniature Proportional Valve | NC Miniature Proportional Valve | NO Miniature Proportional Valve | Miniature Proportional Control Valves

Multi-axis servo amplifier from the DIAS Drive 1000 series can control up to 6 motors. In addition to the housing, the drive regulators also share the controller, intermediate circuit and heat sink. Not only can the construction volume be reduced and the stability increased, the equipment costs ar...

Tag: Multi-axis Servo Drive | Multi-axis Servo Controller | Multi-axis Servo Amplifier for Motor | Multi-axis AC servo-amplifier

English

English Russian

Russian Portuguese

Portuguese