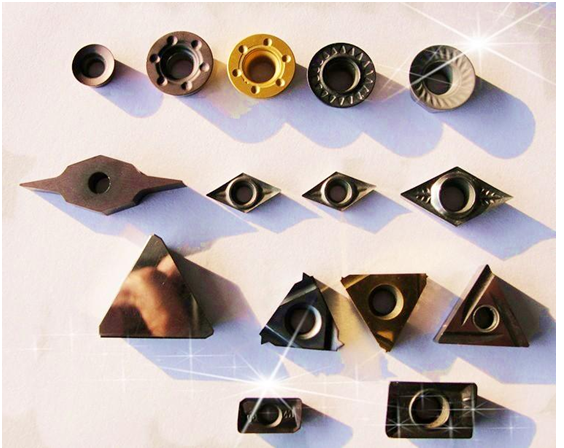

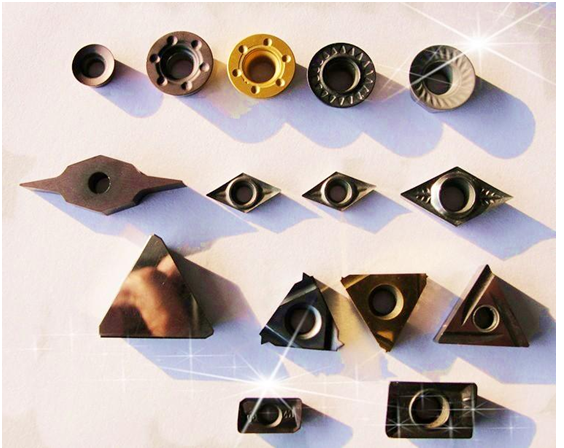

Electric Discharge Machine for Carbide Blades

The dominant way to process carbide blades:

Due to it’s high quality of hardness and wear resistance, carbide is widely used in making blades and cutters. Carbide tools were traditionally processed by grinding and hobbing, a way relies on mechanical energy. But now we produce carbide by electric discharging because it’s thermal energy contributes more to the property of electric processing than mechanical energy.

Attentions:

To reduce the waste of electrode, the peak current should be set carefully. Higher voltage means higher removal rate, as well as higher electrode wear ratio.

About our machine:

Precision and equality in every discharging is specially required in carbide processing. Our electric discharge machine for carbide can precisely check and control every impulse in advance, so as to prevent every possible unusual discharging and other mistakes.

Products made by our electric discharge machines have a smaller hard coat in the surface and easy to be maintained. We have a professional processing system to meet different requirements and make out the work automatically.

Typical Projects